Make An Enquiry

Impact are the label experts so if you’d like to speak to a member of our sales or customer service team, we’d be more than happy to talk through your enquiry over the phone or via email. If you’re a label whiz yourself, instead, fill out the enquiry form and fast-track your price request to our estimating team.

Special Requirements

Please state if you have any special requirements such as express delivery or a specific lead time. Impact can offer plain cover or personally branded delivery notes and work to your individual needs. For example, a 10:30am delivery with a tail lift lorry to a specified delivery point. As well as this, we offer specialist packing, call-off contracts and stock management. Either raise this in your enquiry or get in touch to discuss further.

Material

Label specifications can be a minefield with face and backing material, adhesive and specialist finishes to consider. Impact prints on everything from synthetics, metallic and textured materials to economy paper options. If you’re unsure, simply describe the environment your label is going to be used in and we’ll make sure you get the right product. Consider what temperatures will it be exposed to, will it go in the freezer or will it be exposed to moisture or chemicals, stuck outside or underwater and does it need to be permanent or easily removed.

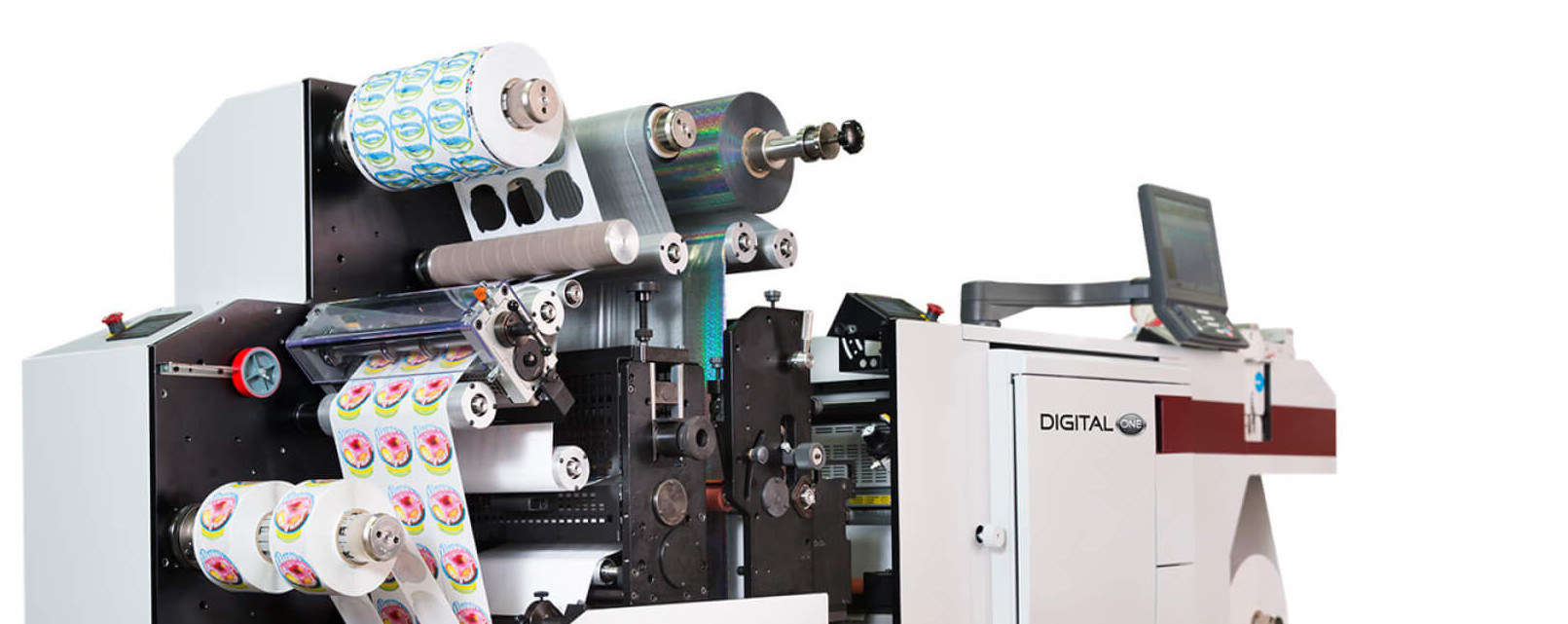

Specialist Options

Impact can do some clever things with labels such as printing on the adhesive or backing and applying security foils and multi-layers, embossing and even braille. We also use some interesting products such as water soluble labels, metallic inks and a range of over varnishes.

Application

If you’re peeling the label off and sticking it onto a surface yourself that’s nice and simple. If you’re using a label applicator or a thermal printer and you know the make and model please let us know. Our experts know how to match your label products to most industry standard machines. This is important as it can influence the type of material or label finishing you require.

The Basics

Start with the label size, shape and gap and whether they’re plain or printed. If you want artwork or a photo of the product we can decifer how many colours are required if you don’t happen to know yourself. Then tell us if you’re going to be overprinting your labels with either a ribbon or direct thermal printer (even better, show us an example of that design as well)!

Roll Label Options

Winding direction is hugely important when ensuring your label is applied correctly. Is it top, bottom, right or left edge leading and is the label wound facing outside the roll or into it? Cores come in a number of standard sizes and your machine may require a specific one.

While we can work to number of labels on a roll, it’s vital to make sure this doesn’t exceed the maximum outer diameter (MAX OD) your machinery or members of staff can practically handle. 1,000 labels that are 200mm long make a very big roll! To keep labels secure on the roll we use glue or tape and add roll end markers to warn when you’re nearing the end of a reel. This is accounted for in the label count (so you aren’t losing out) but if this process may cause you a problem, please do let us know.

Sheet Label Options

With a vast stock of off-the-shelf sheet labels, Impact offers competitive pricing and fast turnaround on plain and short run digitally overprinted sheet labels. These come in various sizes such as A3, A4 and A5, a range of shapes and quantity of labels per sheet. We also produce plain and full colour bespoke sheeted labels with the selvedge waste stripped or retained.

Fan Fold Label Options

Are common with event tickets and thicker materials that do not wrap around a roll easily. They are also popular with logistics labels making it easy to count and tear a specific quantity whilst still on the backing. The backing is perforated to allow folding so it’s crucial to know where you want this perforation to fall (fold length) and how many labels need to appear on each sheet. Fanfold sheets can be several labels wide, split with vertical and horizontal perforations and also tie cuts for easy separation. Impact offers both standard and custom options. We also produce sprocket fed media for older printers.